Need Flexible Feeder Capabilities? Meet the Flex

As the use and influence of robotics continues to grow inside the manufacturing industry, feeding technology must adapt to supplement this development. Flex feeders, sometimes referred to as universal feeders, are designed to present parts in a consistent array so robots guided by 2D vision systems can effectively pick and place parts. The flexible feeder of today must:

- Be reconfigurable to handle many different part geometries without custom tooling or expensive 3D vision systems

- Allow for part separation and manipulation to ensure that robot guided vision systems can easily pick the parts off the feeder

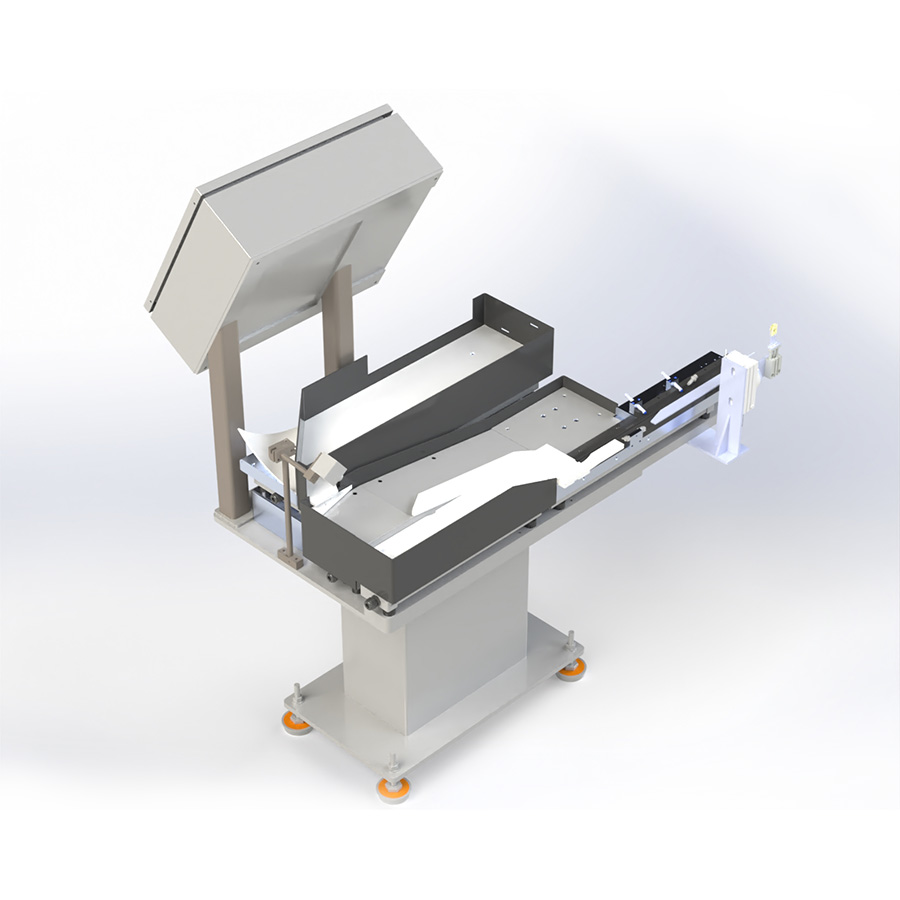

- Integrate easily with robotic arms, gantry systems, and other automation equipment to deliver oriented parts to precise pickup points

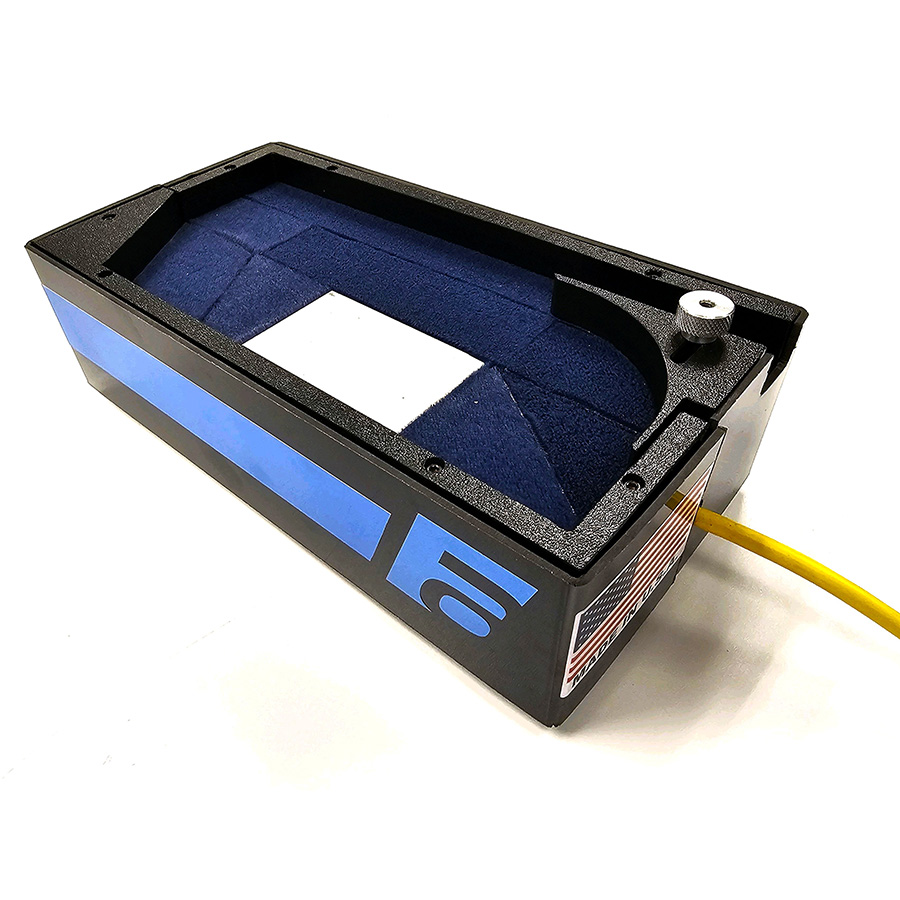

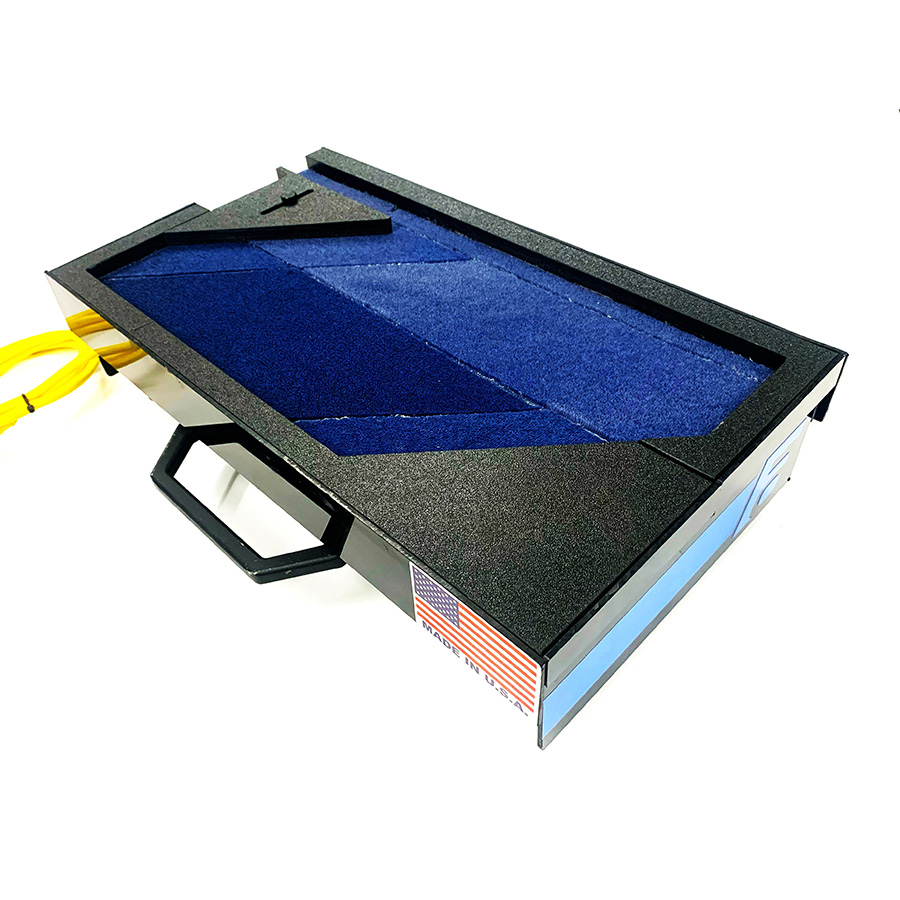

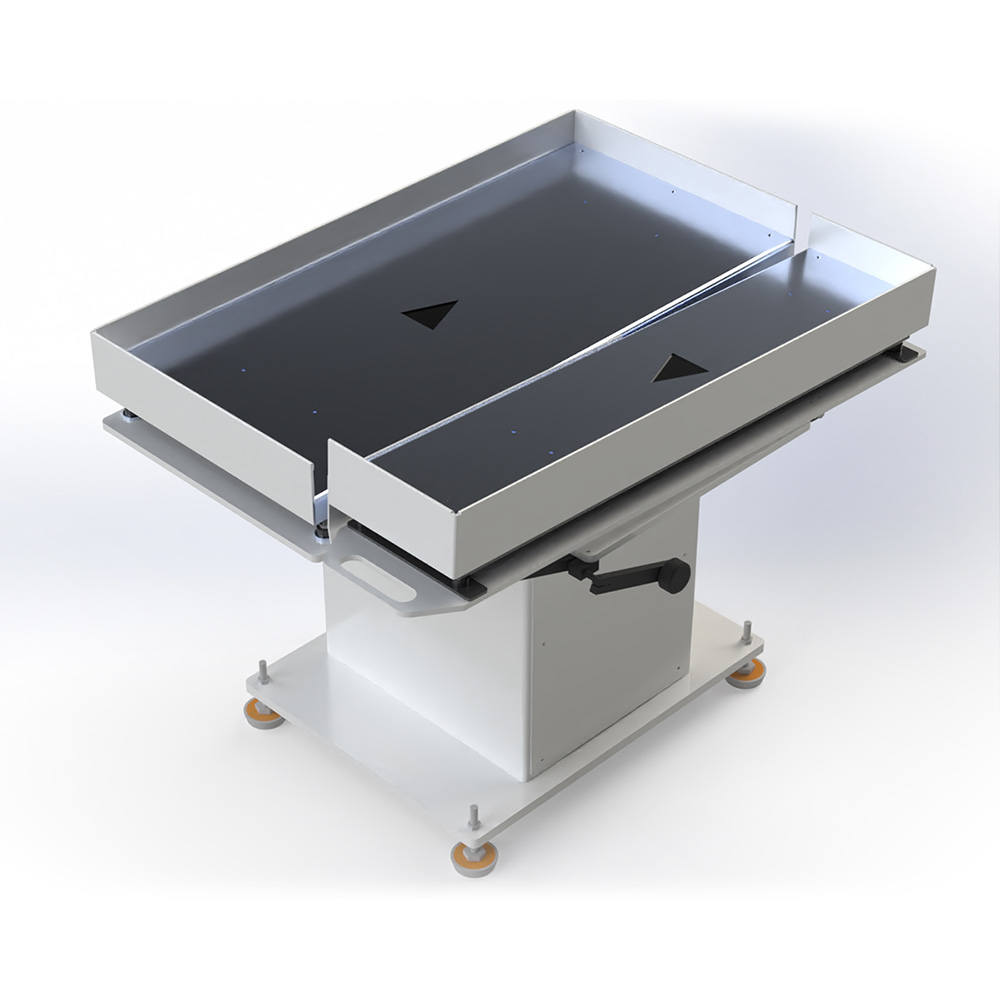

At Feedall Automation, our Feedall Flex flexible feeder is an ideal solution for vision-guided robot or cobot applications. Variable sizes and dimensions allow you to tailor your flex feeder to your specific parts and production line, and both table-top and pedestal-style implementation give you versatility in where you place these automation building blocks. With integrated hoppers, back lighting options, and true recirculating part flow to redistribute unpicked parts, the Feedall Flex series was developed from more than a decade of vibratory parts feeding experience—no other flex feeder can handle a wider range of part sizes, shapes, and weights.

Explore our Feedall Flex. Dive deep into our free automation equipment resources section for in-depth information and visit our Video Library for examples of flexible feeders and other solutions at work. Want to discuss details with our experts? Please reach out at any time.